| map year | Merrick 1 | Merrick 2 | Merrick 3 | Merrick 4 | Merrick Lumber |

| 1884 | not shown | Sanborn | not built | Sanborn | Sanborn |

| 1889 | not shown | Sanborn | Sanborn | Sanborn | Sanborn |

| 1895 | Sanborn | Sanborn | Sanborn | Sanborn | Sanborn |

| 1915 | Sanborn | Sanborn | Sanborn | Sanborn | Sanborn |

| 1949 | Sanborn | Sanborn | Sanborn | Sanborn | Sanborn |

| 1956 | Sanborn | Sanborn | Sanborn | Sanborn | Sanborn |

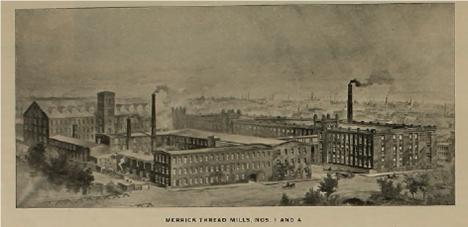

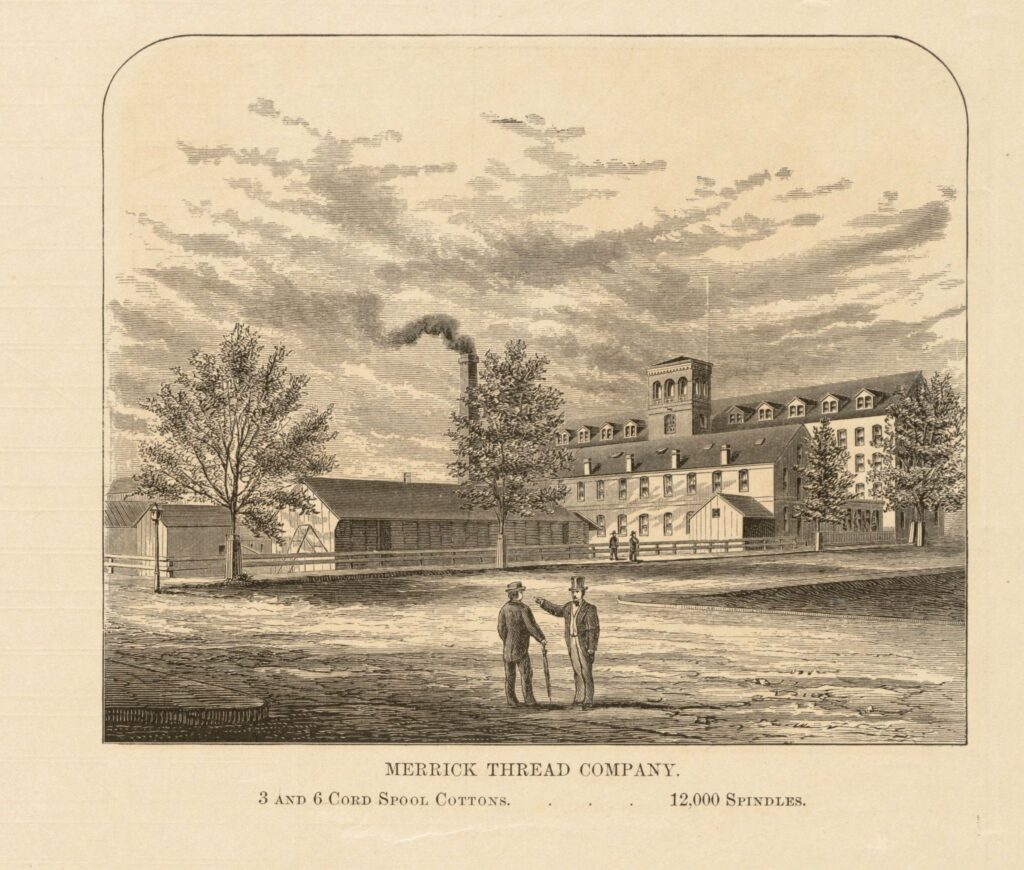

The Merrick Thread Mill was started in Holyoke in 1865. It was ready for production in 1867. At its peak it made 1 million miles of thread a year. Its first mill in Holyoke along the end of the Second Level Canal and the beginning of the Third Level Canal. It had an exposed race coming out of its mill. In 1878 there was a large addition added to this mill.

Merrick Thread Mill number 4 was mostly for administration. It is located across Main Street from mill number 1. It was completed in 1884 and was at first called the Merrick Finishing Mill.

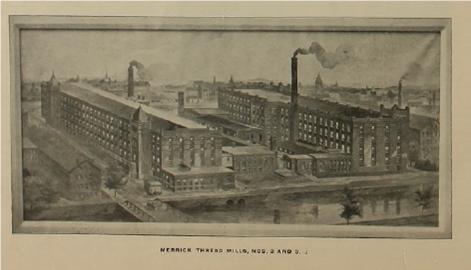

Merrick Thread Mills numbers 2 and 3 are between the First and Second Level Canals at Appleton Street. Merrick mill 2 was built in 1882. Merrick mill 3 was built in 1887 and closely resembled the mill 2.

Timothy Merrick started the Merrick Thread business in Mansfield Hollow Connecticut. He moved it to Holyoke to gain an advantage on his competitors. He was a great mill owner and grew wealthy quickly. He built a mansion on the land that is now Blessed Sacrament Church.

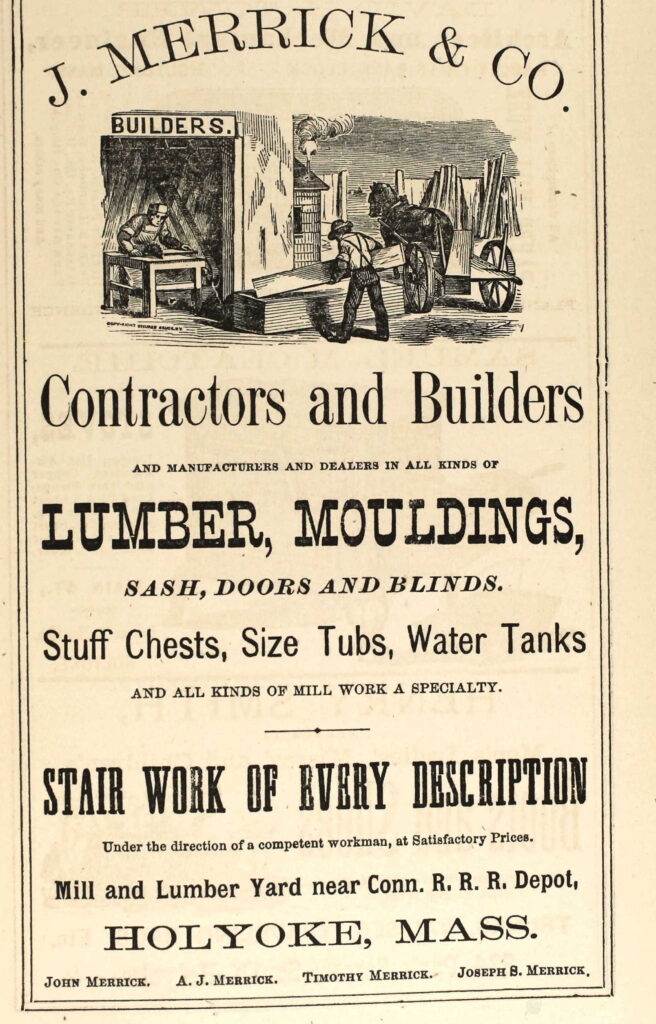

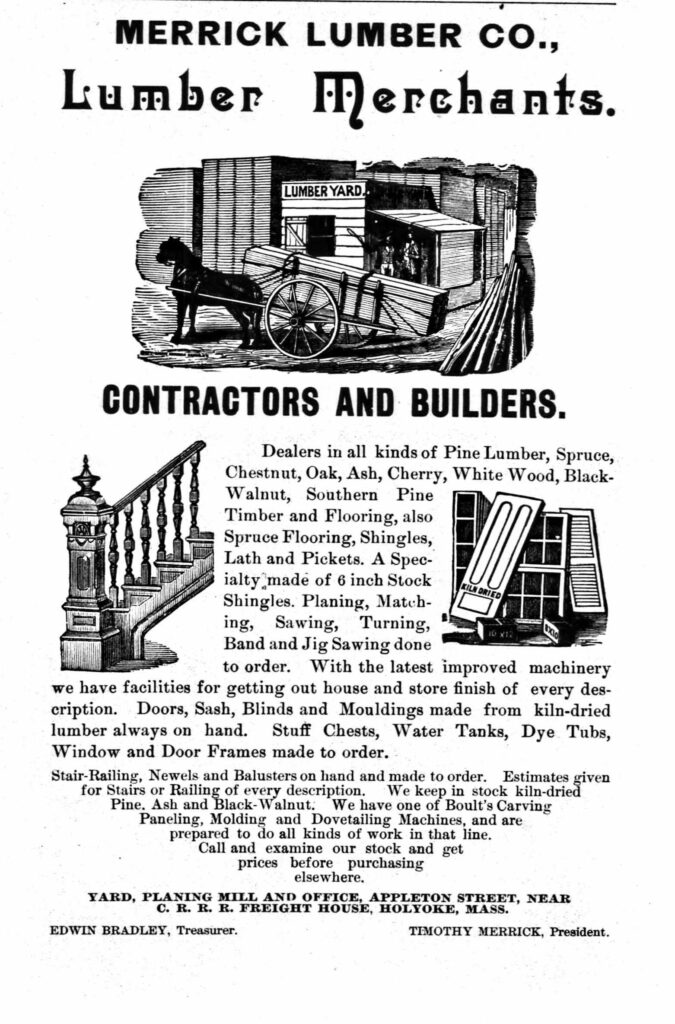

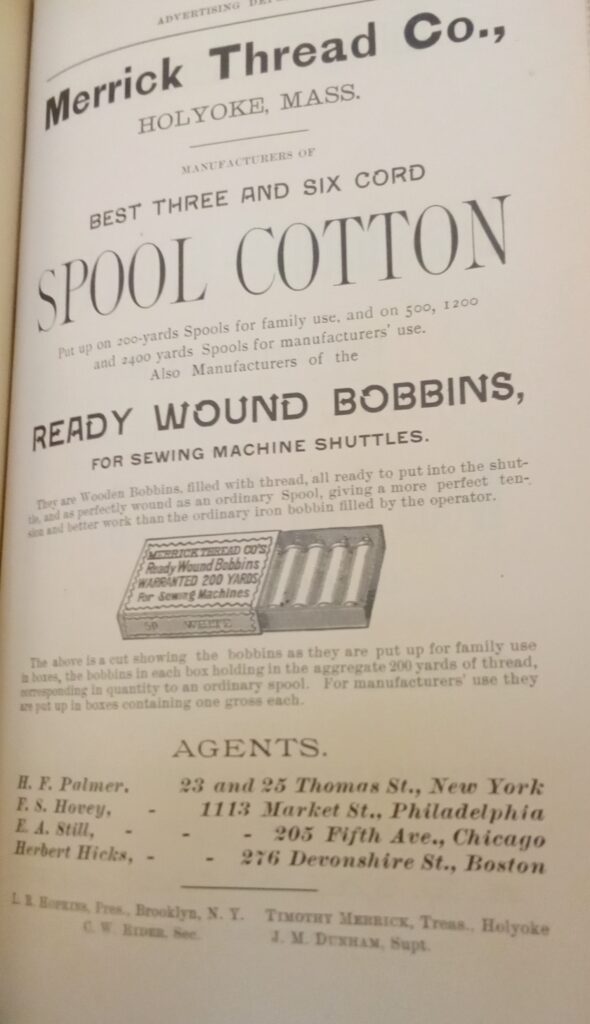

The thread needed to be placed onto wood spools for winding and then distribution around the world. He thusly bought a forest in Lake View Maine to harvest trees. This location in Maine was at the foot of the Schoodic Lake. It was in north central Maine and was on the Canadian Pacific Railroad line. Merrick had his own lumber yard in Holyoke.

Production in the Merrick mills grew at a dizzying pace. In 1886 there was 450,000 dozens of spool cotton and less than 100 workers. In 1896 there was 6.5 million dozens of spool cotton and more than 1400 workers. There were 82 thousand spinning spindles. The Merrick used 1.5 million feet of white birch lumber.

A third of their production was thread and two thirds was twine, warp, and yarn. They had extensive trade in seine twine. Two unique products were linene and silkene which are softer forms of linen and silk.

Merrick imported most of their raw cotton from England who had obtained it from Egypt. Some of their raw cotton came from America with most being from Texas and Mississippi (with the Peeler cotton being the most common).

The Merrick Mill number 4 has been revamped recently and the Baustein Building is now in there with artist quarters. One section of interest is the haunted house – Demented FX.

Current views of the Merrick Thread Mill number 3 are below.